Lubrication and Anti-Corrosion Solutions Inspired by Laundry Pods

Aerospace engineers and entrepreneurs Rob and Daniella Sladen wondered why the same lubrication system design was used for both 15-minute and 15,000-minute missions. Why did oil systems have to be so complex for engines that only needed to run for 30 minutes? The married couple was working on small engines for one-time use drones, when they came up with a concept for a modular oil pod similar to a laundry detergent pod. The pod self-activates to distribute the liquid in and around the working system.

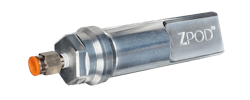

A new approach to fluid delivery for critical mechanical applications, the ZPod from Zulu Pods combines the function of a reservoir, pump and nozzle into a single self-contained and self-pressurized unit. Through patented engineering and design, the ZPod is capable of metering the exact amount of fluid for optimal mechanical system performance resulting in a compact, lightweight and modular system.

In May of 2024, Zulu Pods successfully integrated and demonstrated the ZPod on an engine test stand, satisfying a critical product development milestone. Currently, ZPods are being evaluated for use as primary and backup lubrication systems by the US military. For primary system applications, ZPods replace traditional lubrication systems on jet engines that power UAVs and missiles, affording a significant performance boost in the form of increased range. In backup lubrication applications, the ZPod provides a self-energized emergency oil system independent of the oil pump’s ability to adequately circulate oil to critical mechanical components, thus offering pilots the necessary time to carry out evasive landing maneuvers to safely land the rotary wing aircraft in the event of loss of lubrication. Later this year, Zulu Pods plans to conduct customer engine testing with several engine OEMs, providing a path towards product commercialization, said Zulu marketing manager Tyrone Fitzgerald.

Corrosion protection

Building off Zulu Pod’s patented oil pod technology, the company will also offer pods for corrosion protection for MROs. The Anti-Corrosion ZPod automatically delivers anti-corrosion fluids at customizable intervals for long-term storage or short-term protection during overhauls. Zulu Pods is currently developing the technology Fitzgerald said, and plans to demonstrate its features at the 2025 MRO Americas trade show in Atlanta.

The Anti-Corrosion Pod will provide significant labor and cost savings by incorporating data monitoring of ambient temperature and humidity, mechanical acoustic frequency and pod fluid capacity, he said as well as analytics such as system failure thresholds and operating trends. Data analytics will equip maintainers with valuable knowledge to prevent system downtime and mechanical failures, he said.

Rotorcraft combat survivability during loss of lubrication

Zulu Pods announced earlier this year that it was awarded a Phase 2 contract from the U.S. Army Aviation and Missile Center (AvMC) via FirePoint Innovations Center. The award will continue the partnership between Zulu Pods and the Army focusing on further development of the ZPod novel loss of lubrication pod technology, aimed at enhancing rotorcraft combat survivability during loss of lubrication events for the next generation of military helicopters.

In Phase 1, Zulu Pods conducted instrumented tests on its internal high-speed rig that culminated in the successful validation of its technology through a simulated loss of lubrication event. The tests demonstrated mitigation of bearing failure and performance degradation by delivering minimum oil over time through a static ZPod, upgrading the technology readiness level to TRL 5.

In Phase 2, ZPI is working closely with two major aerospace engine OEMs to continue lubrication testing on bearing hardware, begin digital product integration through engine interface design, and deliver an engine ready prototype for testing and evaluation by the end of 2024.

About the Author

Rebecca Kanable

Assistant Editor

Rebecca Kanable, a veteran journalist, worked with Endeavor Business Media's aviation group from 2021 to 2024 as assistant editor of Airport Business, AMT and Ground Support Worldwide. She previously worked for various publications, including trade magazines and newspapers.