Looking back 25 years, no one would have thought there would be a problem with having enough avgas to fly general aviation aircraft. Today there are price issues and environmental concerns.

There's been a couple of significant events regarding avgas recently. First, a major player has announced its unleaded 100+ octane avgas and the second, the federal government has set aside money for testing candidate fuels and published a very detailed roadmap of the steps for testing fuels from the companies developing candidate fuels.

If everything goes according the government timeline, at the end of 2018 two fuels will be fully evaluated for fleetwide FAA-approved use. For those who haven't kept up, the 2018 date has been mentioned time and again by the U.S. Environmental Protection Agency (EPA) and other regulators as a viable target date for the end of today's leaded 100+ octane avgas.

In this case, fleetwide FAA-approved use doesn't mean that at the end of 2018 these fuels will be flowing at your local airport, it only means that the FAA has thoroughly tested these fuels in engines on test cells and in engines on flying aircraft and that the FAA can't find anything that is detrimental to either the operation of a wide range of engines or to the airframes in which the engines are installed. And that the new avgas is less toxic than today's leaded 100+ octane avgas.

The three companies that have announced that they have viable unleaded 100+ octane avgas formulations have all said that they are willing and able to bring their version of the "new avgas" to market much sooner than 2018. However, the major sticking point of how to get FAA approval for the use of the new avgas in the legacy fleet of aircraft is still unresolved.

The FAA plan

In June 2013 the FAA wrote a Screening Information Request (SIR) for unleaded Avgas. It was presented at the December 2013 American Society of Testing and Materials (ASTM) meeting in Tampa, FL, in December 2013. The title page read: "Purpose: to solicit candidate unleaded avgas formulations for testing to identify the most viable replacements for the existing 100LL avgas with the least impact on the existing fleet of piston aircraft and fuel availability."

Everyone can agree on that goal. Two companies, General Aviation Modifications Inc. (GAMI) and Swift Fuels LLC, have been dedicating considerable time and resources in that direction; four years for GAMI and seven years for Swift. In late 2013 Shell Oil Company announced that it too had a formulation for producing unleaded 100+ octane avgas.

GAMI is a small company best known for its "tuned" fuel injection nozzles. According to George Braly, GAMI's fuel — G100UL — can be produced at any petrochemical refinery without whole scale modifications. G100UL has already passed tests that mirror many of the most recent testing requirements of today's 100LL fuel. Milestones for GAMI include the completion of the FAA's flight testing for certification of a fuel in an airframe with a recognized high performance engine, and the FAA's acceptance of that flight test data. In addition airframe and fuel system compatibility testing, as well as hot temperature/high altitude testing in accordance with the latest (CFR 14 Part 23) FAA certification standard has been completed Testing in accordance with the 150-hour endurance test for engines are well underway. According to GAMI, G100UL has exceeded all test standards.

Swift originally was founded by a small fuels research group that consisted of a Purdue University adjunct professor targeting renewable fuel opportunities. At one time Swift aimed at producing its unleaded 100+ octane avgas from biomass such as wood chips and sorghum. Swift was successful in producing small quantities of its fuel — labeled 100SF — using its process.

Since 2012, new management has changed this intent. In a recent interview, Swift CEO Chris D'Acosta said that the 100 percent biomass route wasn't reasonable for avgas production and that today's 100SF can be produced at a commercially viable cost from petroleum products. In September 2013 Swift Fuels LLC unveiled two pilot-scale production facilities near their offices in West Lafayette, IN. The larger facility will be capable of producing at least 1,500 gallons of renewable fuel components per day; the smaller facility demonstrates its proprietary refinery production processes for low-cost, high octane aviation fuel.

In November 2013 ASTM International recognized that Swift's 100SF fuel complies with all the parameters in ASTM's D7719-13, the "Standard Specification for High-Octane Unleaded Fuel." This means that Swift has a production specification for 100SF. According to D'Acosta no other company except Swift Fuels has an aviation gasoline compliant with an ASTM production specification for 100+ octane unleaded avgas.

In an interview in December 2013, Tim Shea of Shell Oil announced that Shell had three unleaded 100 octane avgas formulations.

All three companies have been working with original equipment manufacturers (OEMs) such as Lycoming, and all three mentioned that Embry-Riddle Aeronautical University had been very involved in a wide variety of flight and test cell data gathering.

The FAA's Piston Engine Fuels Initiative (PAFI) program

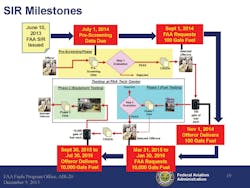

The PAFI program is a two-step program; the first step invites all offerors to submit a formulation package by July 1, 2014. This prescreening phase includes a list of required submissions including MSDS, the fuel test specification, contact information, plans for production and distribution, and a company business plan, as well as other data.

If the company's formulation package passes muster by a FAA Technical Evaluation Committee (TEC) the company enters into a cooperative research and development agreement (CRADA) with the FAA. Data from this phase will be submitted to ASTM International for review and balloting to issue a test specification. By Sept. 1, 2014, the FAA will request 100 gallons of its fuel from the offerors that have signed the CRADA for Phase 1 (fuels) of testing at the FAA Technical Center in Atlantic City. The companies have until Nov. 1, 2014 to deliver the fuel for testing.

Fuels that pass the Fuels Testing (Stage 1) portion of Tech Center testing protocol will move to Phase 2; Equipment Testing. Between March 31, 2015 and Jan. 30, 2016, the FAA will request 10,000 gallons of fuel from each offeror. The timeline for fuel delivery is between Sept. 30, 2015 and July 30, 2016. The projected timeline for completion of the equipment testing phase is three-quarters of the way through FAA fiscal year 18, or around September of 2018. The PAFI plan is to "bless" two fuels. Does that blessing mean the new avgas will be flowing by late 2018? Probably not. In addition to the testing, there are other questions.

The biggest unanswered questions in this process are will all three of these companies (offerors) submit fuels to PAFI? GAMI has said it won't and Shea at Shell in a December 2013 interview stated it was undecided. Will other offerors we don't yet know about submit at the last minute on July 30, 2014 and if so, who? And maybe most importantly, how will the "new avgas" be approved for use in the legacy fleet?

The PAFI statement says: Data collected from this testing will generate data that can be used to support the fleet wide approval of aircraft and engines including the orphaned fleet no longer supported by a manufacturer. This program is the most viable path to a fleet wide approval of new fuel formulations. FAA is committed to develop a fleet wide approval methodology to align with PAFI schedule.

Just how will the data generate a fleetwide approval? The PAFI site mentions one path. If it's determined that one or both of the PAFI approved fuels are "drop in" fuels, meaning that no airframe or engine modifications are required and that the new avgas formulations are fungible with 100LL then the FAA may issue a "Letter of Approval/statement of equivalency" by a policy memo or other method. A fleetwide approval of this sort has never before been done by the FAA.

Both GAMI and Swift are pursuing supplemental type certificates (STC) for the use of their fuels in Cessna 172s. The STC path is seen by GAMI as a faster way to obtain a fleet wide fuel approval. There is a long history of alternate fuel approvals via the STC route; both the Experimental Aircraft Association (EAA) and Petersen Aviation of Minden, NB, have long held STCs for the use of autogas in certified airplanes.

Another alternate fuels approval path was implemented by the European Aviation Safety Agency (EASA) in 2010 for the use of unleaded avgas (not 100 octane) when it issued Safety Information Bulletin (SIB) 2010-31. This SIB granted fleet wide approval for the use of unleaded avgas formulations from Hjelmco Oil Company of Sweden in all certified airframes if the engine manufacturers approved the use of the Hjelmco unleaded avgas. The SIB did not require any airframe testing to use the Hjelmco unleaded fuel.

Will the FAA follow suit and approve the use of the new avgas with the stroke of a pen? Let's hope so.