The Environmental Protection Agency recently developed regulations requiring large airports to collect and store spent aircraft deicing fluid (ADF), treat biologically or by distillation, and either dispose or recover it for reuse. Here, David Delasanta, the president of CASTion, provides background on deicing operations, EPA’s directives, and offers an in-depth examination of one method of mitigation. CASTion has partnered with Contego Systems, LLC, which specializes in eco-friendly methods of collecting spent deicing fluid.

Safety regulations require airplanes to be de-iced with propylene glycol during icy weather, but it can pollute water bodies, kill aquatic creatures, and contaminate drinking water.

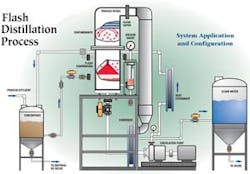

Double-stage vacuum flash distillation in Controlled Atmosphere Separation Technology (CAST) achieves 95 percent recovery of 99 percent pure Propylene Glycol, and provides effective treatment with high reliability, low maintenance, and a high rate of return on investment.

The CAST solution operates at lower temperatures, uses less energy, has a smaller footprint and a quicker processing time than other distillation, and recovers for reuse valuable product that is destroyed in biological treatment.

Source of the Regulation

Congress passed the Federal Water Pollution Control Act Amendments of 1972 — also known as the Clean Water Act (CWA) — to ‘‘restore and maintain the chemical, physical, and biological integrity of the nation’s waters.’’ Congress recognized that regulating only those sources that discharge effluent directly into the nation’s waters would not be sufficient to achieve the CWA’s goals. Airports and their deicing operations will now be required by EPA to regulate their effluent into the environment.

Climate change induced by Global Warming is expected to cause more extreme weather events, including more ice storms and cold weather, leading to a greater need for deicing, and a greater burden on airports from these new regulations.

Since August 2009, the EPA has proposed technology-based effluent guidelines (ELGs) and new source performance standards (SPSs), under the auspices of the Clean Water Act. These standards were specific to the runoff resulting from airport deicing operations. According to EPA guidelines available on its website, “Deicing operations include removal of ice from aircraft, application of chemicals to prevent initial icing or further icing (anti-icing) and removal of (and preventing) ice from airfield pavement (runways, taxiways, aprons and ramps).”

Mandatory Deicing

The Federal Aviation Administration requires airlines to deice aircraft and airfield pavement to protect the safety of passenger and cargo operations. Aircraft deicing involves the removal of frost, snow, or ice from an aircraft. The responsibility for performing deicing/anti-icing varies between airports, but it is usually performed by a combination of individual airlines and support contractors — fixed base operators (FBOs) or ground service providers. EPA estimates that the 218 largest primary airports account for approximately 85 percent of the deicing fluid used nationally. The typical deicing season runs from October through April for most airports; in places like Minneapolis and Chicago, the deicing season may be longer.

Deicing Operations

Airlines typically select procedures for deicing/anti-icing their aircraft, which are then approved by FAA. Although the agency does not require airlines to use a specific technology when deicing, many airlines use aircraft deicing fluid (ADF). These ADFs contain ethylene glycol, propylene glycol, or urea compounds that contain ammonium. During typical wet-weather conditions, 150 to 1,000 gallons of ADF may be used on a single commercial jet, while as little as ten gallons may be used on a small corporate jet. An estimated 1,000 to 4,000 gallons may be needed to deice a larger commercial jet during severe weather conditions.

Centralized deicing pads may be located near terminals and gates, along taxiways serving departure runways, or near the departure end of runways. An airport may use one or a combination of all of these locations for deicing/anti-icing. Road salt (i.e.,sodium chloride or potassium chloride) may be used to deice/anti-ice paved areas that are not used by aircraft (e.g.,automobile roadways and parking areas) but are not considered suitable for deicing/anti-icing taxiways, runways, aprons, and ramps because of their corrosive effects.

Most ADF is applied to aircraft through pressurized spraying systems, mounted either on trucks that move around an aircraft, or on large fixed boom devices located at a pad dedicated to deicing. Airlines typically purchase ADF in concentrated form (normalized) and dilute it with water prior to spraying.

Most of the aircraft deicing fluid is not designed to adhere to aircraft surfaces. Consequently the majority of ADF is available for discharge due to dripping, overspraying, tires rolling through or sprayed with fluid, and shearing during takeoff. Once the ADF has reached the ground, it will then mix with precipitation, as well as other chemicals found on airport pavements. These chemicals typically include aircraft fuel, lubricants and solvents, and metals from aircraft, ground support, and utility vehicles. Water containing these substances enters an airport’s storm drain system. At many airports, the storm drains discharge directly to waters of the United States with no treatment.

Pollution Challenge

Runoff from deicing activity at airports is usually composed of water containing one to 40 percent ADF, grit, and sand. This ADF runoff is not directly dangerous to human health, but when it enters the environment, it can pollute bodies of water with increased organic burden, reducing the oxygen levels in the water. This kind of pollution is defined as COD or BOD (chemical or biological oxygen demand) and is closely regulated by EPA.

Runoff from the deicing treatment process can have the following negative environmental impacts on water quality:

• Contamination of drinking water sources, both on the surface and in groundwater;

• Red water in residential areas and parkland;

• Reductions in dissolved oxygen;

• Fish kills; and

• Reduced organism abundance and species diversity.

Pollution Solutions

In order to reduce discharges of untreated ADF wastewater for the industry, EPA concluded that the best available technology would need to include two basic components. The first is a requirement to capture and collect a specified proportion (either 20 or 60 percent) of available ADF. The second component is a requirement to treat the collected ADF to meet specified end-of-pipe discharge limitations.

EPA recently developed regulations requiring large airports to collect and store spent ADF, treat it biologically or by distillation, and either dispose of it properly to a sewer system or recover it for reuse. The regulations include technology-based effluent standards for discharges from airport deicing operations.

Primary airports with 1,000 or more annual jet departures, and 10,000 or more total annual departures, would be required to collect the deicing fluid and treat the wastewater. Airlines typically select procedures for deicing/anti-icing their aircraft, which are then approved by the FAA.

The new regulations would impose a regulatory and financial burden on airports, requiring them to collect the runoff from the deicing procedures, store it, and either treat it onsite or send it to a waste treatment contractor.

Controlled Atmosphere Separation Technology

The two methods that have been approved for ADF treatment are biological methods and distillation:

• Biological systems use organisms, such as bacteria, which are selected to consume the pollutants and remove them from the effluent.

• Distillation is based on the evaporation of water from the effluent, capturing the vapor and condensing it into a cleaner liquid.

Controlled Atmosphere Separation Technology (CAST) is an advanced vacuum flash distillation system with significant advantages over other methods used, including the added financial benefit of recovering the ADF for reuse or resale.

The central component of the CAST systems is a distillation chamber (still), where heated effluent is sprayed through an atomizer into a low-pressure atmosphere, causing the water to evaporate from the effluent. The effluent becomes highly concentrated, and additional contaminants collect at the bottom of the still, and are removed from the concentrated effluent. The water vapor is collected at the top of the chamber and condensed into water of much higher purity.

After treatment in the CAST system, the effluent is separated into high purity water, a high-quality concentrated solution of the process chemical, which can be reused or resold, and a slurry or solid waste product from the bottom of the still. Pre-treatment components include conventional precipitation and flocculants to precipitate dissolved phosphates and nitrates, as well as granular-activated carbon to remove dissolved organic acids.

In a vacuum, the boiling point of liquids is lowered, so the water evaporates at a much lower temperature, typically 100-140°F, and the heat required to generate the vapor is approximately 1040 Btu/LB of vapor. These low temperatures allow CAST systems to be manufactured with engineering plastics and simple technologies, such as hot water heaters, cooling towers, and pumps.

In contrast, high temperature distillation requires specialty materials and complicated components, such as Freon-based refrigeration systems, or high pressure steam boilers. Additionally, CAST systems can operate on low temperature heat sources, such as hot water heaters, low pressure steam, or waste heat supplies. Operating costs are thus lowered through savings on fuel, and maintenance is reduced through the use of simpler technologies.

The CAST system for propylene glycol, a common ADF, recovers 95 percent of the propylene glycol, meeting ASTM standards at a purity of 99.9 percent. This material can be sold to recover some of the cost of the system. The waste product, which contains five to six percent propylene glycol and dissolved salts, can be disposed of as non-hazardous waste or incinerated.

CAST systems have distinct advantages over alternative options, which include other distillation methods, biological treatment, or reverse osmosis. The reverse osmosis systems are more expensive to install and operate, and the propylene glycol recovered in this manner does not meet ASTM standards, and does not have a value for resale.

In comparison with other distillation techniques, CAST systems have a built-in advantage since they operate at lower pressures. Thus, the system can operate at 125°F instead of at 212°F, as required for other distillation systems. As a result, CAST systems can be constructed from less expensive materials, and require less energy to operate. Since there are no internal parts other than the atomizer and some mist eliminators, scaling is kept to a minimum and maintenance is reduced. Finally, the processing time is better performance, with more gallons of effluent treated per minute.

The advantages of the flash distillation over biological treatment include greater reliability, less variability and sensitivity to operating conditions, and the ability to recover the deicing fluids for reuse or resale. The biological treatment destroys the propylene glycol or ethylene glycol by using it as a carbon source (food) for the biomass.

CAST recovers the ADF for reuse or recycle, with an economic value (currently about $3.50 a gallon). This revenue can reduce the cost of meeting the rule. CAST systems have a smaller footprint than biological systems, have lower capital and operating costs, and produce less greenhouse gases. The biological systems are sensitive to low temperatures and do not work well in the winter, and therefore incur higher storage costs so they can process the PG in the warmer temperatures. CAST systems can operate effectively and reliably under a wide range of conditions, and are appropriate for cold weather operations.