We Can Afford Better: The Compelling Business Case for Advanced Aviation Security Screening Technology

Since 9/11, a lot has changed for aviation passengers. Liquids and electronics need to be removed from bags. Passengers now hold their arms over their heads in body scanners. But the biggest change is wait times. Passengers must allow for up to an hour or more to get through security. While we complain, we usually accept this as the cost for increased security.

But while many things have changed at airport checkpoints, the core screening technology — two-Dimensional (2D) X-Ray scanner for carry-on bags — has not. And while there have been improvements, the same basic technology has been in use for over three decades.

Of course, there is nothing inherently wrong with relying on a mature technology. But in this case, technology has not kept up with the changing threats that face aviation. As a result, screening passengers has become needlessly complex and time consuming.

Experts at the Congressional Research Service concluded that using Computed Tomography at the checkpoint offered higher throughput and better threat detection

Case in point: liquid threats. After the foiled 2006 attempt by terrorists to smuggle liquid explosives onto airplanes, passengers must remove liquids from their carry-on bags. Why? Because 2D X-Ray technology cannot reliably differentiate between, for example, water and hydrogen peroxide. 2D X-Ray's are not designed to detect liquid threats. And as long as they are at the center of the checkpoint, long lines will be a fact of life.

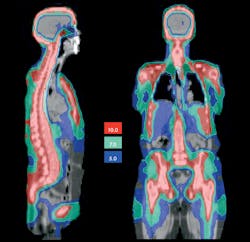

The good news? There is technology recognized as superior to 2D X-Ray – Computed Tomography (CT). Today, CT technology is not only used in medicine to save lives, it is used by U.S. TSA for the screening of all checked baggage because of its high throughput and superior threat detection.

Aviation security experts have long recognized CT’s advantages for screening carry-on bags. The Congressional Research Service compared CT Checkpoint Screening technology with 2D X-Ray and concluded that CT had big advantages: higher throughput, better threat detection, and automated threat detection. Similarly, airport architects and engineers have recognized that using checkpoint CT instead of 2D X-Ray could effectively eliminate bottlenecks at U.S. airports.

If Checkpoint CT is superior to 2D X-Ray for security and reducing passenger wait times, why isn’t it at airport checkpoints? If CT technology is the “gold standard” for screening checked bags, why isn't it used to screen carry-on bags as well?

The answer is the perceived cost of Checkpoint CT – or more accurately, out of date perceptions of cost.

The first generation Checkpoint CT systems were more expensive than 2D X-Ray, and bigger and heavier. And so, Checkpoint CT has been labelled ever since as too expensive to deploy.

But times have changed. The economics of new Checkpoint CT systems are compelling. The latest Checkpoint CT systems are smaller, faster and less expensive. A new ConnectCT Checkpoint system will have double the throughput of current 2D X-Ray, at a price comparable to current 2D X-Ray scanners. The physical dimensions and weight are roughly equivalent to current 2D X-Ray. This means airports can upgrade to a much faster security checkpoint system without incurring re-design costs and without losing valuable real estate.

And, the actual price and deployment cost does not take into account the longer term economic advantages of the newer Checkpoint CT systems. With a higher throughput and lower false alarm rate, a system such as Analogic's ConnectCT would offer airports far greater productivity and operator effectiveness. In other words, one Checkpoint CT system could do more than multiple 2D X-Rays, with the same or less operator effort.

Faster, cheaper, better – and more passenger friendly. It has been a long time since those terms have been used to describe airport checkpoints. But the opportunity is real with Checkpoint CT, all you have to do is check the numbers, and do the math.

Mark Laustra is the Chairman of the Security Manufacturers Coalition, which serves as the unified voice of companies that manufacture security screening technology. Organized under the Airport Consultants Council (ACC), the coalition focuses on aviation and intermodal security issues in the U.S. and globally. A longtime aviation security expert and spokesperson, Mark is also Vice President, Global Business Development, Analogic Corp.