One thing one never wants to do is damage an aircraft while moving it in a hangar. Not only is the plane damaged, but revenue is lost while it is repaired, among other liabilities.

Even with two wing walkers at each wingtip and a towing operator, judging distances can be tricky. Since the tail does not usually have an attendant, the rear of the plane is of special concern. While hangars feature yellow warning lines on the floor, the relationship between the line and the plane is not always crystal clear.

That’s why Talon Air Inc. recently installed a cost-effective perimeter warning system inside its hangars. Talon, a full-service private jet charter and aircraft management company based at Republic Airport (FRG) in Farmingdale, NY, takes pride in running a first-class operation and leading the industry in premier care of aircraft.

Adam Katz, who founded Talon in 2001, relates that the devil is in the details and that adding value at every level is a key ingredient to success. He says the company has increased communication and efficiency by keeping all operational components in-house — from crew planning, operations, and air charter coordination to aircraft management and maintenance.

Using Infrared Light

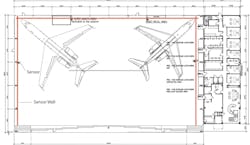

Operating out of a 40,000-square foot facility and a new state-of-the-art 55,000 square- foot facility, Talon wanted to decrease the possibility of a plane being damaged by running into a hanger wall.

A perimeter warning system sounds alarms when a plane comes within eight feet of a wall. “We decided on a perimeter warning system for several reasons. First, of course, is to prevent damage to hangar or aircraft,” says Jay Baron, project architect at Talon. “Beyond that is the peace of mind it brings to aircraft owners as an additional indication of our commitment to first-class service. We’re currently looking into whether it will have a beneficial affect on insurance premiums.”

Talon asked Grid Squared Systems to propose a system solution that would fit the company’s safety requirements. Grid Squared, which specializes in security and automation systems, recommended Optex’s Redscan system for its technical merits and ease of installation and use.

The Redscan system is an intelligent-passive infrared (PIR) detector that uses a laser to scan an area. The laser light reflected back to the scanner allows it to detect a moving object’s size, speed, and distance from the detector. A scanner is mounted on each of the two 156-foot side walls, with two scanners covering the 220-foot back wall. Each system scans an arc of 190° and can cover about 100 feet of floor length on each side, or 200 feet total. Units are mounted 20 feet off the floor.

In the Talon hangars, the detector is mounted vertically so that the scanning creates a virtual laser wall eight feet from the hangar walls. An object breaking the wall sets off an alarm consisting of strobe lights and sirens. While the scanners support up to four PTZ security cameras per unit, Talon already had a CATV security system in place.

No Barrier for Workers

An important requirement of the system is to provide an eight-foot high area for workers to walk in without tripping the alarm. To maintain efficient and flexible working conditions, workers cannot be worried about walls or about having only selected areas to pass from the perimeter to the main floor of the hangar. Intelligent algorithms built into the Redscan system allow this open area to be achieved easily and simply by teaching the system to ignore specific areas during the scan.

Grid Squared, an Optex Redscan Certified System Integrator, installed and adjusted the system in minimal time without disruption to Talon operations. Says Lon Bazelais, senior partner at Grid Squared. “Detection and safe areas are easily defined through software, giving us fast set-ups and excellent control. While some installations have complex requirements to accommodate trees or other obstructions, the Talon hangar by its very nature presented a fairly clean install.”