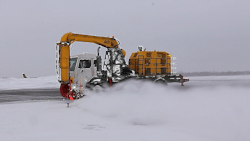

RPM Tech is bringing more power and easier use to the airfield with the third series of the AF1 EVO Cold Air Blower.

The AF1 EVO is used for clearing snow and ice around runway lighting. The burst of air moves the materials away from the lighting without damaging them while performing winter maintenance operations. Airports can also adopt the blowers to remove dust, debris, FOD and other foreign objects on the runway.

“Some airports use it in their conga line,” said Mike Minicucci, senior account manager for RPM Tech. “They will start with the cold air blower right up front and push the snow off the lights and into the runway where the high-speed sweeper or plow is lined up next and they toss it over to the end of the runway. It’s a very efficient machine.”

The third series upgrades include a three-stage centrifugal high-performance blower driven by a diesel engine and provides an air speed of up to 535 miles per hour. The blower module has its own fuel tank and provides up to eight hours of fuel autonomy during operation.

The front spout is no longer in the operator’s view while traveling as it can be stored in the back of the truck. It’s operated via a joystick and touchpad to simplify usage on the airfield. Minicucci said the changes came from airport customer feedback.

“The main feedback was operator comfort because they want their operators to be able to stay in their vehicles longer because in the winter, the snow doesn’t have a set time on when it’s going to fall or how long it’s going to last,” he said. “The better the comfort in the vehicle, the less fatigue for the operator, less danger of accidents and more productivity.”

The AF1 has been produced for nearly 40 years, proving it’s a reliable technology for the industry with upgrades to meet today’s needs. Minicucci said the support is provided with the product.

Operator training for the AF1 focuses mainly on the electronics Minicucci said. It’s a fully computer-based system, where RPM Tech trains them on usage and how to dial in specific parameters for operation.

“New operators coming onto the scene really like technology,” Minicucci said. “They’re all for the touch screens and digital technology, so we’re evolving for that.”

Minicucci said using the AF1 EVO provides operational cost savings by reducing wear on sweeper units. It costs significantly less than a sweeper unit and can be deployed to clear a runway for lighter snowfall.

“It uses ambient air and blows that out onto the snow and runway,” he said. “It doesn’t melt out and create a situation where water is created and ice is formed. It blows it away with the ambient air.”