One of my father's favorite sayings was “use the right tool for the job.” This common sense advice can be applied to the use of BIM (Building Information Modeling) technologies as a tool for airport design, construction and management.

There is a great deal of talk in the industry about what BIM can do. BIM is a digital representation and shared knowledge resource of physical and operational characteristics of a facility. As a three-dimensional tool with an embedded database of facility data, it can serve as a reliable basis for decisions from earliest design conception through the entire life cycle of a facility. As a result, airport owners and operators are eager to embrace this technology as one that can create and manage projects more efficiently and economically and provide a means to more effectively operate facilities in the future.

BIM’s technological capabilities are well-founded, tested and grounded. However, because it is such a powerful tool, there is a learning curve to be able to apply it to its fullest capacity. The first step in successfully integrating BIM into an airport is education. All parties must have a true understanding of what is achievable, practical and cost-effective when using BIM.

It is important to work with clients to discuss and understand both their needs and their desires. The BIM Toolbox offers many options, and it is essential to match these options with the needs of all stakeholders-=- from the owner who may wish to simulate appearance, performance and cost to aid in the design decision and approval process, to the facility managers who will monitor and maintain the systems on a daily basis during the life of the project.

While it may be possible to model every metal stud in a wall to complete quantity take-offs and spatial coordination, the effort may in fact be deleterious, and the value of such detail may be negligible given the cost. Surveying the team’s stakeholders at the inception of the project and collectively agreeing upon the desired uses will ensure that the selection of tools is appropriate to realize the true value in the funds allocated in the implementation of BIM on a project.

Holistic Team Approach

The planning and design phases of a project are generally the easiest phases for airports to integrate BIM. BIM adds value by creating design documents that are more efficiently coordinated.

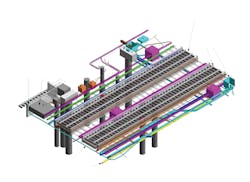

Where many systems cross vertically and horizontally in airports, spatial coordination of building systems during design can virtually eliminate problems previously encountered during construction. One study shows that 18 percent of construction costs typically come from change orders. When the design team implements BIM strategies, that ratio drops to 12 percent. When the entire project team embraces BIM, change order costs drop to 3percent.

While these project savings are made possible as AEC team members manage and share data during design, it is possible to complete a complex set of design and construction documents in a 3-D environment without creating an actual BIM model. To gain the true value of the tool, all team members need to work toward an agreed outcome.

A BIM execution plan is one of the most important components in establishing a structured approach to BIM. This document should identify BIM uses, project goals, procedures, and requirements for modeling, collaboration and communication. The execution plan assigns responsibility for systems, categories and subcategories of elements to team members and lays out the Level of Development (LOD) and spatial coordination requirements for those systems at various points in the design and construction processes. It defines deliverables and quality control requirements at each phase. In addition, the execution plan should define the technology infrastructure-- software, equipment and hardware, and the approach to update that technology in order to maintain continuity during the process.

To ensure uniformity and consistency, the execution plan sets forth the directives, how they will be monitored, and audits at scheduled intervals. It is important, as an airport, to acknowledge that such monitoring is a necessary and independent ancillary task to the overall scope of work for design and construction efforts.

BIM can be used to eliminate the loss of information as a project transitions from the design team to the contractor and finally to the owner. It is essential to establish contracts for all parties that are consistent and referential in order to ensure that each project team is enhancing or referencing information that they have acquired during their particular phase of the project. The owner’s contract for each party should anticipate and acknowledge data transfer between phases and the reciprocal obligations of each party to participate in BIM.

In addition to a document that guides the team, the successful utilization of the tool will also rely on the skill of the team using it. While BIM technology is being rapidly adopted, there are many in the industry who are hesitant to adopt its use, do not use BIM regularly, or who use software that is not compatible with BIM in the execution of their services.

Team members must be equally conversant and proficient in the use of the BIM tools. This is as true for the consultants who may be retained by the airport as it is in-house airport personnel who are assigned as part of the delivery team. Airport management needs to consider both their own technology infrastructure and in-house skill sets, if they decide to undertake a project in BIM and subsequently use it as a facilities management tool or for maintenance of existing condition documentation. Airport leadership must be invested in progressing their projects into the next generation through conscious contracting, open communication with the their team of consultants, contractors and facility managers.

Facilities Management

In addition to aiding in design and construction, the benefits of BIM can extend to support the management of a facility during the entire life cycle of a building. As a combined three-dimensional model and expandable database, there is very little information that cannot be added to a BIM model. If clients begin with that end in mind, the model progresses very specifically at each phase of the project.

BIM can be used to detail how the owner/operator, airlines and other tenants will occupy and use spaces-- a real value to those who manage the commercial real estate aspects of an airport. If product and asset information is incorporated into the model, airport facilities personnel can develop programs for preventative maintenance that use personnel more efficiently and prevent any interruptions to service that might occur due to equipment failure or malfunction-- something that is critical in a 24/7 operational environment.

The air-handling units for a mechanical system may only require limited information for plan coordination early in conceptual design for rough space planning. During construction document preparation, those units can be modeled to include capacity data, connections, maintenance access and even manufacturer selection and associated specification links.

When the model will be used for facilities management, those same units can have information for installed make, model and serial number, O&M manuals and other information necessary for regular preventative maintenance.

BIM can also assist the owner/operator in reducing specific operating costs and to complete cost/benefit analyses to evaluate investment in improvements or new systems. To this extent, those who will eventually maintain the airport and its assets necessarily become collaborative team members with important input into the overall scope of the application of this technology and the use of BIM tools during design and construction. This is another valid reason for beginning with the end in mind.

Planning for the Future

There are few facility types as complex as airports. Competing programmatic requirements, multiple stakeholder interests, security / technical challenges, and the need to be flexible, adaptable and changeable, combine in ways to form an imposing design, implementation and management problem.

The integration of new design technologies influences the successful outcome of any airport project.If the hurdles of understanding how to use the tool effectively can be overcome, the value can be maximized through education, clear goals, defined uses and skilled, collaborative use. As a tool, it is not an end unto itself; rather it is a means to an end and it can certainly be the “right tool for the job.”

Virginia McAllister RA, NCIDQ, LEED AP, NCARB is the principal/owner of Iron Horse Architects, a small business with “Big Business Technology.” Iron Horse Architects has offices in Denver and Washington DC. Virginia’s 25 years of diverse experience in development, design and construction has given her a breadth of experience in the practice of architecture for aviation and transportation facilities.