Taking Plating Technology to the Aircraft

Numerous coatings are available today to protect or to enhance the performance of aircraft components. Surface enhancements include corrosion protection, increasing wear resistance, improving electrical conductivity, enhancing lubricity, increasing hardness, or improving the adhesive bond between cemented parts.

Once the components are put into service and are subject to normal wear and tear, refinishing may be required. For tank plating applications, this consists of removing the damaged or worn component from the aircraft and sending it to the plating shop to be stripped and plated or anodized. In many cases disassembly is time consuming and impractical.

For example, an operator removed corrosion products from cadmium plated steel fasteners. During the process, the anodized coating was removed up to 3/8 of an inch from 1,200 fasteners that ran the length of the wings of the aircraft. The timely and expensive option was to disassemble, strip, reanodize, and reassemble the parts. The more attractive option was to selectively brush plate the individual areas directly on the wing.

Selective plating encompasses a family of portable electrochemical processes that are used on aircraft in both OEM and repair applications. This includes systems that are used for on-site electroplating, as well as portable anodizing and electropolishing. These systems are set apart from traditional tank finishing processes because they can be performed anywhere - in the shop or out in the hangar, and the parts can be plated or anodized without removing them from the aircraft.

Specifications and approvals

Brush plating is widely accepted for use on both military and commercial aircraft. Key specifications include AMS 2451 and MIL-STD 865, as well as numerous commercial specifications from Bell Helicopter, Boeing, Messier-Bugatti-Dowty Aerospace, Goodrich, and Pratt & Whitney; and prime approvals from Sikorsky, Honeywell, GE AE, and Rolls-Royce.

How does it work?

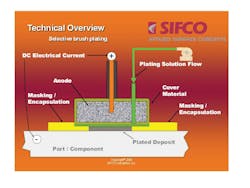

Brush plating and anodizing operations somewhat resemble painting. The operator dips an absorbent tool in a solution and then brushes it against the surface of the area to be plated.

A portable power pack provides a source of direct current for all the processes. The power pack has a minimum of two leads. One lead is connected to the tool and the other is connected to the part being finished.

The direct current, supplied by the power pack, is used in a circuit that is completed when the tool is touching the work surface. The tool is always kept in motion whenever it is in contact with the work surface.

Work surface preparation is usually accomplished through a series of electrochemical operations. These preparatory steps are performed with the same equipment and tool types that are used for the final finishing operation. Good preparation of the work surface is as important as movement of the tools to produce a quality finish.

Adhesion:

The adhesion of brush electroplates is excellent on a wide variety of materials including steel, cast iron, stainless steel, copper, and high temperature nickel-base materials. Adhesion from brush plating is comparable to that of tank plating.

Metallographic structure:

Most brush plated deposits are metallurgically dense and free of defects. Some of the harder deposits, such as chromium, cobalt-tungsten, and hard nickel, are microcracked, much like hard tank chromium. A few deposits, such as cadmium and zinc are deliberately microporous. Brush plated deposits tend to be more fine grained than tank deposits.

Hardness:

The hardness of brush plated deposits lies within the broad range of the hardness levels obtained with tank deposits. Brush plated chromium is somewhat softer; however, a new green alternative to chromium, Nickel-Tungsten (80 percent Ni, 20 percent W) provides comparable hardness to chromium when heat treated and 10 times better wear.

Corrosion protection:

Brush plated cadmium, zinc-nickel, tin-zinc, nickel, tin, and zinc deposits on steel have been salt spray tested per ASTMB-117. The brush plated deposits meet or exceed the requirements for tank electroplates when compared to AMS and military specification requirements.

Brush anodized coatings have been tested and meet the performance requirements of MIL-A-8625E, AMS 2470, AMS 2468, AMS 2469, and BAC 5623.

Hydrogen embrittlement:

Cadmium, zinc-nickel, and tin-zinc plating solutions have been specifically developed for plating or touching up high-strength steel parts without needing a post-plate bake.

The most common deposits used when brush plating aircraft components are cadmium, zinc-nickel, and tin-zinc. These deposits are brush plated onto localized areas of landing gear to repair damage caused by runway debris or other mechanical damage. Additionally, a common application is plating sulfamate nickel to localized areas of engine components to improve the brazing process.

The brush plated cadmium, zinc-nickel, and tin-zinc are low hydrogen embrittling deposits, and can be applied to localized areas for touchup of defective tank plated cadmium deposits without a post-plating bake. They can be applied to the component in-situ, on the plane with minimal to no masking. It is a fast and simple repair - solvent clean, mechanically abrade, and plate.

Brush plating:

Repairing damaged cadmium plating on a landing gear

During a routine maintenance inspection, the operator discovered several damaged areas on the landing gear, including two bushing diameters. There were several small areas of damage that penetrated both the paint and the underlying cadmium plating. This localized damage was a good candidate for repair by brush cadmium plating because it could be done without any disassembly of the landing gear.

Carrying out the repair

The individual defect areas to be plated were solvent cleaned first. They were then mechanically abraded with 120 grit aluminum oxide sandpaper to slightly feather the defect area and to clean the area to be plated.

Because the surface was painted, the only masking that was required was used to catch the small amount of runoff of the plating solution.

The absorbent plating tool was placed into a small container of the cadmium plating solution to soak for a few minutes prior to plating. The positive lead was plugged into the anode, and electrical contact from the power pack was made by attaching the negative lead to a conductive area near the damage.

With the power pack voltage properly set, the deposit was applied by rubbing the saturated anode on the defect area in a circular motion until the calculated ampere-hours (to achieve the desired thickness) were passed. The area was water rinsed and dried.

Bushing repair

The bushing repair was carried out in a similar fashion, with minimal masking to control the solution. The surfaces were solvent cleaned, mechanically abraded, and the cadmium was applied to the bores and faces of the bushings.

Once the plating was completed, the chromate conversion coating was applied to the plated areas for 30 seconds. The areas were rinsed and air dried.

At this point, the repaired areas on the landing gear were ready for the touchup paint to be applied. The plated bushings were ready for service.

Summary

Selective plating is a widely used tool in the aerospace industry for both repair and OEM applications, offering portability, flexibility, and high quality coatings. It can help minimize aircraft downtime and return aircraft to full functionality.

Derek Vanek is the manager of inside sales and technical support at SIFCO Applied Surface Concepts. He has been with the company since 1981, and holds a BS in Business Administration from Old Dominion University. For more information visit www.sifcoasc.com.