Saft’s Worldwide Research and Production Site in Bordeaux Turns 70

Bordeaux, July 1, 2019 – On Saturday June 29, Saft invited staff and their families to mark the 70thanniversary of its global battery research and production site in Bordeaux, France.

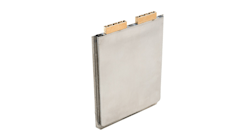

Saft opened the Bordeaux site in 1949 to focus on the manufacture of rechargeable nickel batteries for industrial applications. The factory first big order in 1953 was for the US Navy and the delivery of 2,000 Voltabloc aviation batteries. Today the site exports 76% of its production. It is also one of the largest of Saft’s 14 plants worldwide, covering 78,500 square meters and with a workforce of 700 people including 300 researchers and engineers in research and development (R&D). In 2018, Bordeaux had total sales of €113 million across its range of nickel-cadmium (Ni-Cd), nickel-metal hydride (Ni-MH) and lithium-ion (Li-ion) batteries.

The celebrations were hosted by Serge Llompart, Saft General Manager for the Bordeaux site and Ghislain Lescuyer, Saft CEO. Officials also included Nicolas Florian, the Mayor of Bordeaux, Alain Rousset, the President of the Nouvelle Aquitaine Region and Benoit Simian, Member of Parliament in charge of infrastructure and transportation.

Serge Llompart said: “Our 70-year story at Bordeaux has been one of constant renewal and innovation. Ni-Cd batteries are still the mainstay of the site, as they were back in 1949. But we have refined that technology continuously to provide our customers with new levels of reliability, longer lifetime and reduced maintenance, and we will continue to improve our technology and our customer offering. At the same time, we are proud to have led the way in state-of-the-art Li-ion technology and to be Saft’s flagship research center today.”

Flagship research center

Bordeaux is Saft’s leading research site. It concentrates on development activities and is also home to Saft’s electrochemistry, systems and production research. A key development in 2016 was the establishment of an incubator to work alongside mainstream research to bridge the gap between fundamental research and close-to-production prototyping. The incubator comprises three teams covering: chemistry, optimizing the electrochemistry; systems, battery integration and management; mechanical, developing packaging structures, connectors, cooling systems and safety features.

“Our history is very important to Saft. In 2018, Saft celebrated 100 years in business. Now we are delighted to mark 70 years in Bordeaux,” said Ghislain Lescuyer. “Key to our success is that we are always looking forward. Which is why we place such a great emphasis on R&D. That is demonstrated by our latest initiative in co-founding the European Battery Alliance, to develop next-generation solid-state batteries that will be safer and more energy efficient than their predecessors. Today, we have around 40 employees working on this program in Bordeaux.”

Production for global markets and customers

Production at Bordeaux is focused on cells and batteries for rail and aviation customers. These include major global rail manufacturers such as Alstom, Bombardier, CAF, Hitachi, Siemens, and CRRC, the Chinese rolling stock manufacturer. In the aviation sector, customers include Airbus, ATR, Comac, Dassault, Embraer and Sukhoi.

In addition to transportation, batteries from Bordeaux are used widely in industrial standby applications.

For renewable energy customers, an important activity is the integration of Li-ion cells manufactured at other Saft sites into containers for megawatt-scale energy storage systems (ESS).

A digital future

One person who has witnessed the evolution of Bordeaux is Jean-Louis Liska, Product Safety Manager. He started at the site in 1984 and has worked in a variety of product development and engineering roles. He says: “When I first came to Bordeaux it was mainly a manufacturing site with a lot of manual assembly operations. That has changed significantly with the advent of automation, while the research facilities have expanded enormously. What excites me for the future of this site is the speed at which we are adopting digital technology at every level. For example, the use of 3D visualization and 3D printing is now almost routine. We are also embracing the Internet of Things (IoT) by implementing remote monitoring of our batteries for condition-based service offerings.”