In the early days of aviation, aircraft used onboard DC batteries to power their radios and other electrical equipment. However, as planes started carrying more electrical equipment, the demand for more power capacity at the lowest weight possible led to the adoption of engine-driven DC generators and with the jet age the need for even more power and lighter weight became necessary, which spawned the development and use of 400 Hz AC power systems.

Originally, ground support operations used diesel motor-generator sets to provide the power while the plane was on the ground. While these mg-sets provided pure sinusoidal power and high overload capabilities, they did so at a fairly high capital and operating/maintenance cost not to mention the noise and pollutants to the environment. Today, with the development of the new diesel engines, which make the pollutants much less, the higher operating and capital costs are still a consideration factor.

The development of the solid state frequency converters in the mid 1980s significantly reduced all the costs (capital/operating/maintenance/weight/size) and they produced no pollutants. The only drawback to choosing solid state units was the fact they needed a 60 or 50 Hz 380/480volt input source instead of diesel fuel. However, in remote areas (where diesel units are normally required), many times it would be much cheaper to run electrical cable to where a solid state unit could be used than to pay the added capital expenditure difference and constantly spend a lot more for the diesel fuel and maintenance costs associated with diesel GPUs. The key as to which to use, is determined by the operational needs (military and extremely remote sites aside) is really the overall cost of ownership and reliability factor.

Today, the vast majority of frequency converters sold in the United States are solid state rather than rotary, which is again not always the best or most economical way to provide 400 Hz power. The decision to go with solid state or motor generators is one that should not be decided by the available annual capital budget set aside but by a study by knowledgeable and experienced 400 Hz engineers who do take into account all the factors involved in cost of ownership which includes, maintenance, reliability, equipment life, quality of power (in and out) esthetics, reputation of service by the airport or airline, noise, and pollution to the environment.

The decision of what to use or buy when it comes to aircraft power systems must be made by a truly knowledgeable, and responsible individual or body, based on all the factors and not by the initial capital cost or a budget, but by the overall cost and total operational needs.

Solid State Considerations

If solid state is determined to be technically the solution to your needs, then the following must be considered.

Most solid state frequency converters continue to use the original design which consisted of silicon controlled rectifiers (SCR) to convert AC voltage into DC voltage and then use an insulated-gate-bipolar-transistor (IGBT) equipped inverter to form the 400 Hz waveform for the output voltage. The output of the inverter section is then filtered and smoothed to meet the requirements of the aircraft, which has been published in MIL-STD 704F.

The advantage of this design is that it uses easily controlled, inexpensive components. The disadvantages are that the units can be electrically and audibly “noisy,” as well as needing frequent adjustments of their analog control circuits due to environmental conditions. The less expensive units will also need more frequent replacement of the power capacitors that are used to smooth the output waveform.

Because SCR rectifiers cannot take in sinusoidal currents, they will distort the utility input current. The negative impacts of non-linear loads on the quality of the electrical energy supply are called system perturbations or more generally electrical pollution. This includes harmonics, flicker, transient faults, asymmetric and voltage outages. For units that are equipped with controlled or uncontrolled rectifiers and capacitors in the DC-Link, the input current waveform is far from sinusoidal. They create high harmonic distortions in the input current waveform. They lower the input power factor taking more reactive current and they induce commutation spikes into the utility power supply.

Any device that draws a pulse of current from the electrical network for less than the entire voltage wave generates harmonics. Harmonics are simply a mathematical representation of these distorted waveforms that allow us to model electrical network response at multiple frequencies, and better understand and predict how the electrical network will react to this high-frequency content — or “electrical pollution.” The worldwide standard IEEE 519-1992 requires that end users limit harmonic levels to ensure network stability for all users. It outlines acceptable levels of harmonic distortion (both voltage and current) and the point of common coupling (PCC) with the utility.

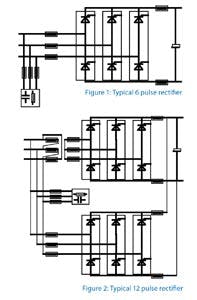

There are two alternative designs to reduce the above effects of the simple “6-pulse” rectifier. The first is to use more SCRs in the rectifier which has led to “12-pulse” and “24-pulse” designs. The second is to use IGBTs in the rectifiers as well as the inverters. IGBTs have several advantages over SCRs. They do not have to be turned on and off at the zero crossing point; they do not change the input power factor or induce commutation spikes into the input power source. They also allow better control of the entire power and frequency conversion process. For these reasons, IGBTs are now being used in high end SSFCs just as they are used in state of the art solid state uninterruptible power supplies (UPS).

To better understand the above points, let’s look at how each of these devices is used in the typical SSFC. A low end SSFC will have a pair of SCRs for each phase of the power source “6-pulse.” One SCR is turned on for the positive portion of the AC waveform and turned off at the next zero crossing. While the opposing SCR of the pair is turned on for the negative portion of the AC waveform and off at the next zero crossing. This on/off pattern is used to transmit full power to the output load.

A 12-pulse SCR system follows the same basic pattern but it splits the utility power into two 6-pulse rectifiers. The second 6-pulse rectifier is typically fed through a 30-degree phase shifting transformer. This provides a smoother DC current which puts less stress on the DC capacitors and shifts the input current harmonic distortion to higher frequencies with less energy content, but the design requires more components.

For both rectifier types (including versions with diodes instead of SCRs) the energy will follow one direction only, which means the energy is only fed to the load. There is no way to absorb energy from the load and transmit it back to the utility.

IGBTs are also used in pairs for each phase of the power source. Instead of turning on and off at the zero crossing point, IGBTs are fully controlled using a pulse width modulation (PWM) control algorithm.

PWM systems typically operate at much higher switching frequencies (6 – 8 kHz instead of 120 Hz for SCRs) which eliminates most of the audible noise. The higher switching frequency allows much finer control of the power conversion process. It also does not produce the audible noise that is often found in low-end systems. The width of each pulse determines the amount of power that is converted to DC in the rectifier. But, because there are thousands of pulses in each cycle the energy being transferred per pulse is small which gives the IGBT system significant advantages over an SCR system.

Since the transistor can conduct the current in both directions, it is possible to feed some power back to the utility in case the load creates some reverse power. This is another significant advantage over an SCR system (simple no break power transfer capability).

Electrical Noise

Whenever loads draw current in a non-linear manner, such as that experienced with rectifier based equipment, harmonic distortion is experienced. Harmonic current generates heat in all of the current carrying components of the electrical distribution system. The system includes not only the converters but also the upstream switchgear, breakers, fuses, cabling, capacitors, bus ducts, bus bars and transformers. Based on the higher frequency, harmonic current generates more heat on a per-Amp basis than current at the fundamental frequency (50 or 60 Hz).

The current requirements for SSFC units range from tens of amps to several hundred amps. The percent of distortion is thus very large at low current levels and improves as the amount of current rises. This is why most manufacturers only give the amount of harmonic distortion at full load. Typical levels of THID for six pulse rectifiers are listed in Figure 3.

The % THID is representative of systems which do not have any means of filtering included in their input circuit. Filtering will lower these values at the expense of overall system efficiencies.

These THID values are high at lower loads, because the SCRs are turned on later in the waveform. The later in the waveform the SCR is turned on, the greater the harmonic distortion that is reflected back into the utility grid.

The IGBT design produces much lower harmonic distortion (<5%) compared to the SCR design on both the input and output waveforms. Therefore, whenever efficiencies and unit losses are measured, the total system losses should be measured at each load point. This will provide a better measurement of the energy requirements for the system and not just the individual piece of equipment, especially when that piece of equipment generates large losses in the upstream cables and transformers of the system.

Input power factor

A power factor of one or “unity power factor” is the goal of any electric utility company since if the power factor is less than one, they have to supply more current to the user for a given amount of power use. In so doing, they incur more line losses. They also must have larger capacity equipment in place than would otherwise be necessary. As a result, a facility will be charged a penalty if its power factor is much different from one.

SCR rectifiers present a variable power factor to the utility. Typically, the lower the load is, the lower the power factor that is presented to the utility and the more power the utility must supply. Generally, at a 30- percent load, the power factor is 0.6 or less. As the load approaches full load the power factor will approach 0.8. Factors that affect these values are input voltage (the higher the voltage the lower the power factor) and the construction of the output inverter.

IGBT rectifiers present a 1.0 pf to the utility independent of load and input voltage. This means that there is no phase shift between voltage and current and thus no reactive power is required from the utility. This means that there are no additional losses at the utility power distribution center and the utility feeder cables. The required current is as low as physically possible. This results in lower operating costs for the units. This will increase the system efficiency (minimize the losses of the input power feeder run) and will not create any problems with any other loads that use the same feeder subsystem.

Commutating gaps (High spike voltages)

Due to the higher switching frequencies of the IGBTs, there are no switching/commutating notches (see the blue trace below and the oscilloscope screen capture) of the input voltage. The SCR design requires a short time when two phases are both on. This causes a momentary short circuit which tends to collapse the voltage waveform which causes the notch. This “noise” is sent back to any equipment that is being powered by the same utility source. Without proper filtering, this “noise” can damage electronic circuits and shorten the life of the equipment. Because the commutating gap also distorts the incoming power waveform, it requires the utility to provide more energy to compensate for the line losses. This results in higher operating costs for these SCR units.

No break power transfer capability

Most of the newer aircraft, especially the wide body aircraft, require a so-called no break power transfer. During this transition phase, the SSFC and the internal auxiliary power unit (APU) of the aircraft are working in parallel to prevent any interruption of the power while switching over from internal power to external power. Since there is no precise synchronization and no load sharing /load transition regulator in place, the APU could feed some power back into the SSFC (reverse power).

SSFCs with SCR rectifiers contain a risk that some components might be damaged during a reverse power condition. In this case, additional hardware (chopper with resistor, etc.) must be used to “burn” the reverse power, since it can not be transferred to the utility directly. Even with additional hardware, the inner components are stressed by higher voltages during the transition phase. This higher stress and a number of additional components will decrease the reliability of these units.

SSFCs with IGBT rectifiers will transfer the reverse power directly to the utility and thus do not need any additional hardware. Since no components are stressed by higher voltages created by the reverse power, the reliability of the unit is not decreased and there isn’t any additional risk of malfunction.

Conclusion

While 6-pulse SCR rectifier SSFC units are slightly cheaper than IGBT rectifier SSFC units, they have some significant drawbacks due to their effect upon the total system.

As energy prices continue to increase and power quality considerations and system reliability become more important, the construction of the input rectifier becomes a more important factor. IGBT rectifiers will optimize the energy consumption of the system and will reduce long-term operating costs providing users payback within a short time. The long- term investment for IGBT rectifiers is secured by eliminating the risk of “electrical pollution” and the negative influence to any other equipment on the same power system. In addition, they can handle reverse power conditions without any decline in the operating life time.

For further information please go to the White Paper section at www.piller.com.