1. What sets a tire apart for GSE? Is it efficiency and durability, or what else do you measure success by?

I would say success is measured on the ramp primarily by the number of service hours a tire provides. We can take this figure, along with other metrics, and calculate the cost per hour a particular tire offers the end user. To achieve a lower cost per hour you ultimately need to be a more durable option, that provides an exceptional rate of tire wear. Equally important is fuel savings. In today's marketplace with more stringent emissions regulations, Continental not only provides a more durable option in our RV20 Velocity tire, but at the same time a more fuel efficient option through tires with a naturally low rolling resistance. Lower rolling resistance can lead to improved fuel consumption with internal combustion engines, leading to lower exhaust emissions. Additionally, lower rolling resistance leads to extended battery life in battery-powered GSE.

2. What can GSE maintenance teams do to extend the life of their tires?

The primary thing maintenance teams can do is maintain consistent and proper air pressures in their tires. Running on low air pressure is an all-too-common thing that leads to premature wear and tire failure. Second would be avoiding foreign objects that can also lead to premature failure. The latter cannot always be controlled. Conversely, air pressure with a good maintenance protocol can always be controlled.

3. How can regular tire maintenance increase the useful life of high-wear equipment like baggage carts and pushbacks?

Again, air pressure is key in extending any tire's life. Proper inflation can reduce wear and heat buildup due to excessive side wall flex and ultimately help prevent premature failure. This can be especially key in GSE vehicles as most do not have suspension systems to help absorb vehicle shock and thus the tires are the primary suspension. Along with air pressure, regular visual inspection of tires can spot potential issues that may extend the tire's useful life if addressed early.

4. Continental is well known as an automotive consumer tire brand, what sort of breadth does the company offer the GSE market?

The Continental Commercial Specialty Tire (CST) business unit offers a complete product portfolio of pneumatic and solid type tires that cover a wide array of applications from material handling to earth moving. This includes everything from forklifts and sea-port cranes to dump trucks and loaders and everything in between. The spectrum of sizes currently represented starts at 4 inches and goes all the way up to 35 inches. The CST product offering for GSE specifically, covers baggage tractors, belt loaders, PCAs, air starters, lav carts, pushbacks, cargo loaders, jet bridges, etc. Additionally, we have our passenger/light truck and medium truck divisions that help supplement our GSE tire offerings.

5. You and Continental (Booth 432) will be exhibiting at the International Airport GSE Expo in October. What’s new in the industrial tire world and what can attendees check out when they visit you at the Expo?

Continental will have several of our popular GSE tires on display such as the RV20 and RT20 as well as some of our more material handling related tires. One of the things Continental benefits from is we are more than just a tire manufacturer. We are one of the leading original equipment automotive suppliers for both electronic technology as well as chassis and interior products. Continental leads the way on many innovative passenger car products such as lane detection technology, infotainment, engine and vehicle management systems to name a few. We supply many, if not most of the major vehicle manufacturers. As such we are able to leverage and utilize these technologies for use in other divisions of the company. One such innovation is our ContiPressureCheckTM system. This is an onboard vehicle system that monitors both heat and pressure in the tires and alerts the operator to issues with either. The system can be adapted to a wide array of vehicle and machinery applications, including many GSE vehicles. We will have this on display as well.

6. How important are sustainability and emission-reduction programs in the current economic environment?

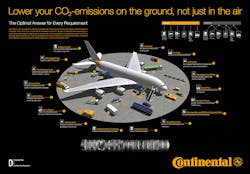

I read a recent GSE equipment market study that indicated that electric (battery) operated ground support equipment is forecasted to be the fastest growing segment over the next five years. This is due in large part I am certain by the regulated push for lower emissions. As I mentioned previously, tires with lower rolling resistance have a part to play in helping reduce these emissions. Continental has been a proven leader in achieving lower rolling resistance across all segments of our tire divisions: Passenger, Medium Truck and Industrial. It is a pillar of our tire building technology if you will, and is very important to sustainability and emission reduction strategies now and into the future.

7. What’s the most important thing you’ve learned as you work to expand Continental’s GSE customer base?

I would say the most important thing I have learned is that value in terms of durability, reliability and operating savings is key. Everyday the GSE and airline industry as a whole conducts a very orchestrated and fine-tuned operation which relies on a lot of moving parts. Delays happen if any of these moving parts break down. Delays cost time and time costs money. Our goal at Continental is to help our customers reduce these "breakdowns," specifically as they relate to GSE tires, as much as we can. That is why we overengineer our tires, so they deliver the best overall value to our customers.

8. What would you like to see change in the industry?

From a tire manufacturer's perspective, I would like to see more of the airlines and GSE equipment manufacturers take their GSE tires more seriously. I can say this is actually happening now. In my experience, I have seen all kinds of "odd ball" tire applications on the ramp. One good example: baggage tractors are not cars, they don't handle like cars, they are subjected to different weights, speeds and forces, so why do we continue to see passenger type tires used in a GSE "industrial type" application? The same can be said for many other types of GSE equipment.

9. From a business perspective, we’ve seen a lot of consolidation as companies combine to create complete product portfolios. How have the dynamics of the industry changed the way you do business?

To be honest, not much really. We do rely on several different business segments (passenger, commercial truck and commercial specialty tire business units) within our organization to help deliver a vast and complete product portfolio. Additionally, we have our other automotive and technology divisions that we are incorporating more and more into our tire business to help progress and develop new products that benefit our customers.

10. Many of the environmental factors on the ramp (maneuverability, weather, foreign objects) are similar to driving on the road, but the vehicles are obviously vastly different – even from each other. Is Continental able to share IP across applications, even with vastly different product requirements?

Yes, absolutely. I think one of our key strengths is the diversity of technologies within Continental and our ability to share these technologies through out the different divisions of the company. We are always looking for ways to improve our products and implement knowledge and/or innovation within the organization. As technology continues to grow, we'll look to stay nimble and continue applying these innovations into tires and supporting products that move the industry forward toward smart and sustainable solutions.

Chris Bennett is a territory sales manager with Continental Tire. He has 20 plus years of experience in both marketing and sales within the automotive aftermarket. His tire background covers all facets; Passenger/Light Truck, Medium Truck and Industrial. He has been with Continental since 2008. For more information visit www.continental-specialty-tires.com.