A Caster that Drives Productivity

When dealing with cargo, efficient ground operations are critical. Moving more cargo equates to more success. But that cargo needs to be transported safely, not just quickly.

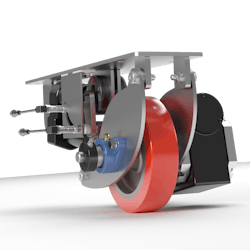

With this in mind, Caster Concepts has developed the Drive Caster – a self-contained, motorized caster for carts, dollies and other applications.

“Once a total load exceeds 2,500 pounds, it is very difficult to move it manually with a traditional caster configuration,” explains Mike Kulka, director of sales at Caster Concepts. “We had customers and prospects that wanted to move up to 6,000 pounds and above. In response to their needs, we developed the Drive Caster so that these loads can be moved effortlessly.”

There are two different packages of Drive Casters available. The standard package with controls and a battery unit can be mounted directly to an existing piece of equipment. The other option is the company’s conversion Drive Caster, which is a separate unit that can be attached and detached to the item ground handlers need to move.

“We have refined it and standardized the unit to an 8” wheel with a ½-hp motor,” Kulka explains. “Certainly, special options are available – wheel size, motor size, powering options, etc.”

A single Drive Caster typically travels at 1-2 mph, and can move loads up to 5,000 pounds. However, using multiple Drive Casters in tandem increases load capacity.

“We have utilized eight Drive Casters to move a 30,000 pound total load,” Kulka recalls, noting the Drive Caster was originally developed four years ago, and Caster Concepts launched it full scale to the market in 2016.

For the Drive Caster to operate, a control module and battery are required. Typically, customers purchase these items from Caster Concepts too, but Kulka says customers can wire and power a unit themselves, if they prefer.

“We believe the Drive Caster can assist in moving any stand or piece of equipment that has been difficult to move with traditional casters,” Kulka says. “Many times, moving these items can lead to injuries or potential downtime concerns.”

Because the Drive Caster utilizes a standard 4.5” by 6.25” top plate and standard overall height, the product can be modified to fit the height restraints of existing caster configurations.

“Drive Caster moves significantly more weight than similar products in the market place,” Kulka says. “It is easily specialized as well, which is a differentiator compared to other pushers.”

Kulka adds that a swivel Drive Caster is the next evolution of the unit. That technology is being developed and will be available soon.

Because the unit offers flexibility, Caster Concepts’ ground handler and airline customers have provided positive feedback, noting improved efficiency and fewer worker injuries associated with pushing and pulling.

“The Drive Caster takes the possibility of worker injury out of the equation and allows improvement in process flow,” Kulka says.

To spec the appropriate caster for an operation, Kulka says customers must consider whether cargo will be moved manually, determine traveling conditions and note the size and weight of the equipment. Ground service providers should also consider total load, duty cycle and speed when selecting a caster solution. What’s more, extreme temperatures can influence a caster’s ability to perform over a period of time, Kulka warns.

“Many Caster Concepts casters are now maintenance free wheels and swivel selections,” he points out, adding a standard preventative maintenance program is always recommended. “A caster that is not specified properly can lead to worker injury and/or damage to the unit being moved. The more information about the application the better.”