The Borescope Market in 2023

As the features and cameras in everyday devices, from your phone to the PC, continue to grow more advanced, so do the cameras giving maintenance technicians an inside view of aircraft. In 2023, scopes articulate, read temperature, have interchangeable probes and more – with a single unit having multiple features.

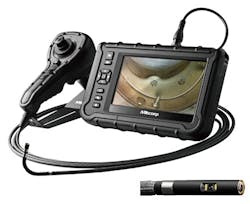

VJ-4 Video Borescope

The VJ-4 from ViewTech Borescopes can be used to inspect every turbine engine from a PT6 to a GE90. Very small diameter scopes are available for inspecting sub-assemblies, castings and avionics.

Sean O’Connor, general manager, ViewTech Borescopes, said one of the first things a VJ-4 user will notice is that the six or eight control buttons typically found on feature-rich scopes has been replaced with two, easy-to-reach mini-joysticks.

“These mini-joysticks allow the user to navigate and adjust every function, setting and menu. Alternatively, you could use the touchscreen, which has the same capabilities,” said O’Connor.

Ensuring the scope was ergonomic was a key point of the borescope’s design, and the result of thousands of conversations with aircraft maintenance technicians and other borescope users during the past 15 years, he said.

“We worked with Disher Design in Zeeland, Michigan, on the ergonomics, balance, and controls placement, and with Walker Studios in Traverse City (Michigan) on the icon designs and menu/file structure,” he added.

The ease-of-use design philosophy was extended to the scope’s user interface and menu structure, which O’Connor described as “absolutely intuitive.”

“For an experienced borescope user, there really is no learning curve. Every function is right where you’d expect it to be and easily adjusted with the mini-joysticks or touchscreen,” he continued.

Other features include:

- A rechargeable Li-ion battery with a three-hour run time.

- HD OLED touchscreen and onboard image processing image quality, with stylus for on-screen annotation.

- 10-stage LED or fiber and LED illumination.

O’Connor’s advice to get the most out of any borescope is simple – slow down, don’t rush your inspection. Performing a deliberate, conscientious inspection will result in much better images and video, and it will greatly reduce or eliminate accidental damage to the scope.

He added common mistakes users make with the scope are:

- Putting images and videos in the wrong folder.

- Not using the near/mid/far distance settings to achieve optimal image quality.

- Being careless with a long insertion tube and letting the camera module hit the floor.

“Typically, a borescope either works well or it doesn’t work at all, there isn’t a lot of grey area. If a scope is handled properly, the lens cover is kept clean and special care is taken while inserting and extracting the insertion tube during an inspection, there’s no reason a good borescope shouldn’t last many years without any problems,” he continued.

USA 750 J

Designed and developed specifically with the aviation industry in mind, USA Borescopes officially released the USA 750 J earlier this year. The USA 750 J is one of the smallest HD borescopes for inspecting turbine blades, airframes, bores, and castings without removing or disassembling the finished component, said Bill French, sales representative, USA Borescopes.

French said the scope has been designed with inspecting every part of the aircraft in mind.

“Turbine inspections, piston, you get some of the prop planes have piston engines, gearbox inspections are being done with these, you get airframe inspections that are being done with these,” he continued. “It’s a little bit of everything.”

The scope is a handheld, modular design with the probe and control station together. The control station can detach from the articulating probe and users are able to mount that control station onto different diameter probes, as well as different length probes.

“In the aviation arena, the thing that really sets this system apart is a couple of nice features. One, it does have a dual camera tip, so for many borescopes out there, especially for PT6 inspectors, they have to screw on a side viewing tip. So this system here actually has two cameras at the tip, one that looks straight ahead and one that’s at a 90 degree side view. So the inspector, he doesn’t have to get in there and mess around with the articulation at all,” French said.

The scope features a 5-inch HD touchscreen, joystick articulation, digital zoom, photo or video recording in 1280x720pc via a Micro SD card, EV adjustment, 8-character text annotation and Wi-Fi app compatibility.

Notably, the scope can withstand a temperature range of 0°C to 60°C and comes with a built-in temperature sensor to alert technicians when damaging temperatures are present.

“So, as you’re entering that engine, if it’s too hot in there, an alarm comes up on the screen advising that mechanic or borescope inspector to remove the probe from that inspection area, let it cool down. And we realized lots of times that happens because it’s a priority issue, maybe it’s an AOG situation and they want to get on it quick, but you don’t want to damage your investment by introducing that probe tip to an environment that is too hot for that camera,” explained French.

For getting up to speed with the scope’s features and capabilities, French said overall the scope is user-friendly and online videos are available to help technicians get familiar with the USA 750 J.

More importantly, French said is avoiding damaging the scope. After use, the scope should be cleared of debris and foreign substances, and the scope should always be returned to its case, even between frequent uses.

“A common mistake that we see is people just keep the scope out on the shelf because they want to get to it quickly when they need it, but we strongly recommend when you’re done, store it in the case that it came in. That probe is pretty fragile. We don’t want someone coming up and dumping their toolbox on the probe and kinking or denting the borescope probe. So clean it before you put it away and put it away in the case that it came in, because that’s the best protection you give it,” French said.

Recon Pro

Designed and manufactured entirely in-house, the Recon Pro is built to handle all standard visual inspection applications, with its most notable feature being its interchangeable probe system.

“All of the camera probes can change, can be taken out, removed from the unit and new ones can be replaced within the same unit so the same unit becomes very versatile to deal with multiple different camera capabilities,” explained Jared Hartley, business development coordinator for SPI Borescopes.

Camera capabilities include ultraviolet, infrared and street viewing cameras, which face directly ahead of the camera probe.

“We have 90 degree side view camera probes, which face 90 degrees perpendicular to the end of the camera cable. And then we also produce dual view cameras. They have cameras both facing 90 degrees and straightforward that you can toggle between to get a fuller view of the component that you’re inspecting,” added Hartley.

Recently, SPI added working channel probes, which have a small working channel tunnel going through the length of the camera probe towards the end, which we can then send retrieval tools through. “There is a claw option, a lasso, multiple different types of claws actually to retrieve small components lost within an engine turbine, or nuts and bolts that were dropped,” said Hartley.

The Recon features four different image enhancement settings for navigating inspections in different environments, such as for looking at bright or highly reflective metals, or viewing dark materials that require a high contrast to see the damage.

These settings and more are built into the Recon’s software, which in addition to the probes, are always being improved

“Every year people are leveling up, especially us, leveling up their inspection equipment and these are very expensive pieces of equipment, so we do have upgrade programs to make it extremely easy for our clients to upgrade. So those interchangeable probes, we constantly increase the camera capabilities of the probes,” said Hartley.

SPI provides upgraded probes and equipment that technicians can easily swap without needing to purchase a new scope. They also have a swap and repair program, in which SPI swaps broken or outdated probes with newer ones.

Hartley added SPI is looking to upgrade its software to an Android system later this year, then migrate all of their clients’ units to the system, which will allow for measurement, annotation and an even better user experience.