Exova, the leading global testing, calibration and advisory services provider, has expanded both capacity and technical capabilities at its aerospace laboratory in Santa Fe Springs, California.

The investment includes new state-of-the-art Computer Numerical Controlled (CNC) grinders, mills and lathes. Additionally, the lab has invested in waterjet capabilities, expanding its cutting services into new technologies that deliver high-precision multiple-axis cutting. These new technology investments will support a 35 percent increase in capacity that meets customer requirement for an average three-day turnaround of test results.

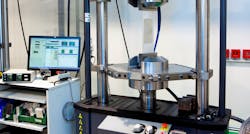

The Santa Fe Springs laboratory provides specialist metals testing, fatigue and high temperature fatigue testing, creep/stress rupture, metallurgical and chemistry testing. It supports aerospace primes and leading organizations in their global supply chain and is one of 14 Exova aerospace testing facilities worldwide.

Rocco Moro, Executive VP for Aerospace in the Americas, comments: “In the highly competitive aerospace market, speed and efficiency is crucial and this investment means our customers will benefit from significantly improved workshop processes, reducing the specimen production steps and ensuring faster delivery of results.”