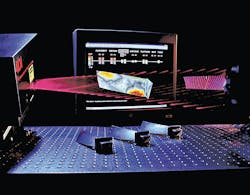

Lightscan blade inspection

Related To:

Dec. 10, 2008

The Lightscan non-contact blade gauging inspection from GE Inspection Technologies is a complete, automated, shopfloor solution for quickly and accurately measuring compressor blade airfoils for comparison with CAD data to obtain immediate go/no go sentencing. The system offers significant cost- and time-saving advantages over conventional hard gauge inspection and is the first system of its type to feature both measuring sensor and associated application software, providing a total turnkey inspection solution. Using white light technology, the operator-friendly, Lightscan has a typical inspection cycle of just 20 seconds, compared with the 60 to 90 seconds required by competitive equipment. It is accurate to greater than 0.0005 inch, which is comparable with more cumbersome CMM equipment, and it can be programmed to inspect new parts in just four hours. For more information visit www.geinspectiontechnologies.com.