The composite repair industry is driven by a world of ever-evolving products made from composite materials. New ideas, services and products are constantly being conceived, prototyped and developed. Composite Repair companies have respond to these innovations by designing new ways and methods of supporting the composite manufacturing process and fielded unit repair.

New Developments

In 2020, the basic requirements have not changed all that much, explained Dave Junkin, president of WichiTech Industries. Heat and vacuum are still needed to cure most composite repairs. However, R&D efforts continue to look for one of the “holy grails” of the composite repair industry: a universal resin that cures at room temperature. “In fact, WichiTech is currently partnered with another firm to develop and produce a DC hot bonder to work with a new, low temperature prepreg,” Junkin noted.

“In the ‘old’ days, OEMs would ask is it possible to do something; nowadays, the OEMs are asking how you can reduce the costs associated with composite cures,” Junkin said. In keeping with this theme, WichiTech answers with new ways to apply the best techniques. There is a company in Canada that has developed a virtual reality training system for the company’s composite repair systems. Technicians can be trained remotely by qualified instructors in the correct methods and procedures for operating WichiTech bonders in an ultrarealistic and sensory immersive virtual reality experience.

WichiTech developed the first portable composite repair set, the CR1, more than 30 years ago. The CR series was designed specifically to perform small area repairs on the Starship manufactured by Beech Aircraft, which WichiTech says is widely regarded as the first all-composite aircraft. “The CR was created to address localized defects from the manufacturing process or damage that occurred after delivery,” said Junkin. “WichiTech came up with a portable, suitcase-sized hot bonder that could be easily taken anywhere and only required a standard electrical outlet to operate.” This hot bonder was used to apply localized heat and vacuum (pressure) necessary to cure the thermoset resins available at the time. The portable hot bonder concept has been copied many times since, the company noted.

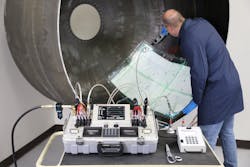

Heatcon, which has been in the business for 40-plus years, has developed an innovative composite repair system called the Smart Susceptor hot bonder, which uses inductive heating to apply heat during the curing process. “The advantage of this system is that unlike traditional hot bonders, inductive heating allows the heater to self-regulate its temperature to maintain a very precise temperature across the heat blanket,” explained Heatcon president Eric Casterline. “This is very useful for complex composite parts where normal heat blankets are unable to provide even temperature.”

For example, a thrust reverser cowling has both a thick, honeycomb sandwich structure for its primary structure, and thin, solid laminate flange near the edge of the cowling. In addition, there are frequent fittings attached, which act as heat sinks. If a traditional heat blanket is applied to a structure such as this, a technician may need to use multiple heat blankets in combination with insulation and a bit of trial and error in an attempt to achieve uniform heating during the cure. “With this approach, technician training and experience is imperative,” he noted.

Smart Susceptor technology uses a combination of induction heating and the magnetic properties of heating wire to overcome this challenge. The heat blanket itself is engineered to self-regulate when the material cure temperature is approached, allowing the heater to thermally adapt to the part and provide extremely uniform heating. In trial studies, Heatcon has been able to show up to a 300% improvement in temperature uniformity.

What Customers Want

WichiTech has found that its standard HB1 and HB2 hot bonders meet and often exceed most current customer requests. Through the integration process, WichiTech can modify a “standard” hot bonder to meet almost any specific customer request. For instance, the standard HB2 uses industry standard quick connects to implement vacuum source and measurement hookups. One large commercial aviation company asked WichiTech to forego the quick connects and implement the connection via press-fit connectors. These changes were implemented and shipped as a new configuration of the standard HB2 model.

“There are currently 15 HB2 configurations and eleven HB1 configurations available to address the specific needs of a customer,” explained Junkin. “These include different voltage/current, number of measurement points, explosionproof/commercial, DC/AC operation, networkable and several more.”

Stepping Into The Future

WichiTech has found that many customers are reluctant to add more capability if it requires a re-training of their core personnel. Specifically changes to the operator interface can be difficult. Many WichiTech features and improvements are “hidden” behind the interface to suit both the production line (where changes are somewhat frowned upon) and the laboratory setting where the engineering staff is always looking for more precision, more data, etc.

“Along this line of thinking, we enhance our products through accessories or functionalities,” Junkin noted. “Always conscious of cost, we seek solutions that build upon what the customer already has or is familiar with. A good example of this is pcLink, a software/hardware package that allows the capture/control of data from the hot bonder to a PC.” The software allows the direct capture of real-time temperature/vacuum values, alarm status, etc. into an Excel spreadsheet. pcLink supports a realtime graphing of an ongoing cure and, through the PC, offers an almost unlimited storage of cures. Additionally, it updates all data once every 10 seconds.

WichiTech is also involved in developing a standard hot bonder serial protocol that will allow the interconnection of many different hot bonders in the future. pcLink does currently support the interconnection of up to fifteen HB2 and/or HB1 zones.

Teaching & Training

The number one factor affecting the successful outcome of a composite repair is the knowledge and skill of the technician performing the task, according to Junkin. A comprehensive training program in composite material science, repair methods and procedures is an absolute requirement for all technicians and engineers involved. “The exponential increase in the application of composite materials for aircraft structures has outpaced the training required to perform repairs to these advanced structures,” explained Junkin.

Application consultation and training has become an integrated part of what Heatcon does as a business. “Every customer has unique needs depending on the parts being repaired, materials being cured, facility requirements and OEM repair procedures they are required to follow,” said Casterline. “Our focus as a repair equipment OEM is on the use and application of our products to meet our customers’ specific needs. We also work closely with aircraft OEM training organizations and professional training organizations such as Abaris Training.

Composite repair requires a great deal of tactile skills associated with damage removal, taper sanding and other surface preparation methods that are usually done with a high RPM angle grinder. It also requires a great deal of knowledge about the constituent materials (resin, fiber, core, etc.) in the structure, the fiber axial orientation of each layer and a fundamental knowledge about vacuum bagging and cure processes. This includes understanding thermocouple placement and how to use hot-bond process equipment. These skills take time to acquire and must be practiced to stay proficient.

“Training has evolved over time with the industry to use more common and efficient repair methods and techniques (for example: taper scarf vs step repair), noted Lou Dorworth, direct services manager, Abaris Training. “A great deal of emphasis is placed on teaching students the underlying fundamentals of composite materials and processes, reinforcing why a certain method or process is prescribed in the repair instructions. This approach is far better than just teaching a student how to do a repair. The best courses are designed to promote the ‘why’ and practice the ‘how’ so the technician or mechanic is inclined to follow best practices.”

Dorworth says the deployment of large aircraft composite primary structures has shifted the discussion from a decade ago where repairs to fairings and control surfaces were common, to now where repairs might include highly-loaded fuselage and wing structures. “Technically, the approach to repairs is the same, but on a far greater scale and with flight critical consequences if a repair is to fail,” he explained. “As a result, there are far more process steps and quality checks involved in the repairs and training is stepped up to address these requirements.”

Most companies have their own safety guidelines, but many of the more common requirements can be taught in class, Dorworth notes. Classroom discussion of the various routes of exposure, protection methods and composite specific concerns such as handling solvents, resins, fibers, and avoiding carbon splinters is all part of the curriculum. Personal protective equipment (PPE) is a fundamental part of composite repair training where gloves, shop-coats, eye protection and dust masks are employed for protection from exposure. Other hazard and safety awareness is brought to the students as they encounter issues in the workshop. In general, it boils down to promoting common sense.

When it comes to prepeg materials, Dorworth says they are much better suited for high-performance applications and are often prescribed for repairs to primary structure. “A number of Abaris courses use prepregs and hot bonder processes in their repair training,” he said. “Having said this, wet layup materials are still valid for limited applications and we still teach students the proper methods and techniques for achieving quality repairs.” It is important to note that the general aviation (GA) community uses a great deal of wet layup for repairs that fall within the guidelines of the structural repair manual. Abaris has a course specific to GA repairs.