Having updated their range of 2015 courses in early January, Dark Matter Composites has taken just 6 weeks to build and launch their new website to better complement the range of services and equipment offered www.darkmattercomposites.com

“Although we know dust free trimming and repair activities are possible, seeing is believing! At the recent JEC exhibition numerous people were sure that dust free carbon fibre sanding was impossible, until they watched our video showing how effective our step sanding tool kit was. We have now embedded our full set of high definition training videos for this equipment onto our website.”

The new website now has video content that demonstrates what is possible with a wide range of extracted air tools along with guidance on selecting the right tools for the right job. For instance:

- Diamond coated drill bits work best at high speed, and drilling at 20,000rpm will prevent de-lamination. Combined with an extraction shroud and our portable dust extractor, set to mid volume and mid pressure, will ensure a clean dust free working environment.

- If you need to sand vertical surfaces or component edges use a 3” orbital sander with a small orbit, mesh abrasives and our dust extractor, set to high volume and low pressure, will also provide a dust free working environment.

“As specialist composites suppliers for Dynabrade & Festool we needed to make it simple and easy to purchase the correct equipment. We use these tools and can recommend the right solutions, nobody wants to waste money on equipment that isn’t fit for purpose, or doesn’t last. That’s where we can help. The effectiveness of air tools combined with on tool extraction, in the right configuration, can save time and money and reduce risk.” Rodney Hansen, Managing Director.

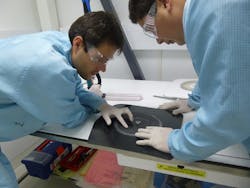

Dust control is an increasingly important issue for trimming, drilling and repair activities, and these tools are proving to be a popular choice. As experts in training and consultancy for the composites industry, Dark Matter Composites can demonstrate how to get the best out of the equipment it provides.

As training providers it is our responsibility to ensure training is up to date and taught to the highest standard. To assist with this we have aligned our repair courses with the requirements of the SAE’s AIR4938 standard, 'Composite and bonded structure technician/specialist training document'. This standard was produced by the worldwide 'Commercial Aircraft Composite Repair Committee' (CACRC) and defines the foundation content and structure for composite repair training that is applicable to all industry sectors.

Our stage 1 and 2 composite repair courses already covered cross sector repair techniques with a full range of materials, processes, tools and techniques and were already 90% in line with the AIR4938 standard. As all our courses are already in line with the UK’s National Occupational Standards for composites and fully documented to the UK’s Qualifications and Curriculum Authority requirements, it was a relatively easy task to cross reference to the AIR4938 standard and add 10% more technical content to our repair courses. The end result is that all our customers benefit from the work we do for aerospace.

The range of equipment offered is being expanded along with video content and our course information has been fully updated with guidance notes. The new website also allows:

- multi currency for British Pounds, Euros and US Dollars

- on-line booking with delayed credit card capture so we ensure there is a place on the course before taking payment

- offline payment invoicing

- delivery prices calculated for world destinations

This allows our customers to book courses and order equipment at any time, on any day, from wherever they are in the world.