Compressor washes are a routine procedure for those who work on gas turbine engines. Some mechanics might think it is just another mundane task we must do. But why do we do compressor washes? Well, the answer is more than, “because it is written into our operations procedures.” Let’s take a look at compressor washes and how they affect engine performance and life cycles.

Thermal efficiency

Taking a look back at what we learned in A&P school, we see that thermal efficiency is a prime factor in gas turbine performance. AC 65-12A tells us that thermal efficiency is the ratio of net work produced by the engine to the chemical energy supplied by the fuel. The three most important factors affecting thermal efficiency are turbine inlet temperature, compression ration, and the component efficiencies of the compressor and turbine. Other factors that affect thermal efficiency are compressor inlet temperature and burner efficiency.

Contamination to the compressor section affects the thermal efficiency, and therefore the performance of the engine. Not only does it affect performance, but damage to the blades caused by contamination can lead to engine failure.

Contamination

So, what causes contamination? Well, it has to do with the atmospheric environment. The atmosphere, especially near the ground, is filled with contaminants. There are fine particles of dirt, oil, soot, and other foreign matter in the air. Because of the large volume of air introduced into engine compressors, a lot of this contamination is introduced into the engine. The centrifugal forces of the compressor throw this contamination outward so that it builds up to form a coating on the casing, vanes, and the compressor blades.

The accumulation of these contaminants reduces the aerodynamic efficiency of the blades, resulting in deteriorating engine performance. The efficiency of the blades is reduced in a way similar to the way ice buildup reduces the lift efficiency of a wing. This loss of efficiency can lead to unsatisfactory acceleration and high exhaust gas temperature (EGT). Contamination, especially in high salt operating environments, can also lead to corrosion of the engine components.

In order to maintain engine performance and reduce the corrosive effects on the engine, the debris that builds up in the compressor needs to be removed. We do this through routine compressor washes.

Compressor washes

So, how does a compressor wash remove contaminants from an engine? AMT talked with Bruce Tassone, president of ECT inc. ECT manufactures R-MC compressor wash. “The chemicals in a compressor wash solution break down the organic bonds of the contaminants,” Tassone shares. “This then allows the air stream and/or the fresh water rinse to remove the contaminants out of the engine.”

The OEM specifies which chemicals can be used to wash the compressor. The approved list can vary from manufacturer to manufacturer. “Some OEMs have a specific list of approved washes,” says Tassone. “Others refer to a military specification like MIL-C–85704 or set specific chemical parameters.”

Tassone stresses the importance of using proper chemicals like R-MC. “There are different parameters you have to meet with a compressor wash,” he shares. “Using unapproved engine washes could cause damage to the engine or airframe such as corrosion, acrylic crazing, hydrogen embrittlement, stress corrosion cracking, and other defects.” In order to avoid damaging the engine, be sure to use only authorized chemicals. “You should ask your supplier or overhauler for certification that they meet the engine and airframe OEM specifications,” stresses Tassone.

Premix or concentrated?

Compressor wash can come in either premixed or concentrated forms. How do you know what type is right for you? “Some customers buy premixed if they are concerned with either the labor associated with mixing and/or the quality of water they can secure,” Tassone tells AMT. “If they have space concerns, such as inventory storage, or they want to be a little more cost-effective in terms of the transportation, and they have the capacity to blend the chemical in regards to labor pool and water quality, they may tend to go with concentrate.”

Water quality

Water quality is an important part of effective compressor washes. Whether it is for mixing the concentrate or for the rinse portion of the wash, proper water needs to be used. “We, as well as the OEMs, always recommend de-ionized or de-mineralized water,” says Tassone. Don’t be tempted to use tap water. Doing so can introduce contamination back into the engine you are trying to clean out.

Establishing a wash schedule

Compressor wash schedules will vary from one operator to the next. The frequency of wash events relates to the amount of contaminants being ingested into the engine. Operating environment, as well as the types of flight profiles, both affect contaminant levels. “High cycles impact the engine,” shares Tassone. “But flight patterns also do. If you are dealing with a commuter such as a turboprop, where you are doing shorter runs at lower elevations more closely tied to the city, then your fouling curve is going to increase. If you are looking at trans-Atlantic flights, your fouling curve may not be as steep, but you may have ancillary impacts such as the inorganic and salt buildups. So you have multiple effects with respect to the engine.

Each operator needs to develop a compressor wash schedule that best meets their operating situation. “Most operators set compressor wash schedules with regards to their specific situation,” Tassone tells AMT. “They will look at what their degradation curve is. And either individually or with us, they will do an economic analysis of what the breakpoint is for the best wash frequency, and then tie that task in to whatever would be the appropriate checkpoint in their maintenance schedule. In a salt environment, it could be a wash every day because our product has corrosion inhibitors. It could also be on up to a three- to six-month cycle.”

Tips for effective washes

Compressor wash procedures vary from manufacturer. A typical compressor wash involves three steps — a chemical wash, a water rinse, and an engine run.

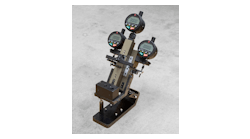

After connecting the appropriate fixtures to the engine, a chemical is injected in the engine while the compressor is turned. Firms like ECT manufacture the wash equipment to conform to the OEM flow rate and pressure recommendations. This allows the chemical to be ingested into the compressor section where it breaks up the molecular bonds of the contaminants. The wash is followed by a fresh water rinse. The rinse ensures that all of the contaminants dislodged by the wash are flushed out of the engine. This is followed up by an engine run. The airflow from the engine run helps further clean out the dislodged contaminants, and dries out the engine.

Tassone shares the following tips for effective washes:

“First and foremost, they should always refer to the OEM procedures, because they are engine specific. Second, products that are biodegradable and nontoxic yield high cleaning efficiency while improving personnel safety and lowering disposal costs. If solvents are used, make sure the proper collection, disposal, and government reporting are maintained. Third, we can’t emphasize enough that high-quality water, both for mixing and for rinsing, is very important. Finally, they should be using injection hardware and equipment that is approved by the OEMs or their engineering group to ensure they are getting a proper wash and not introducing FOD hazards. The mechanics should inspect to ensure all hardware is secure so that foreign objects are not ingested into the engine. Using correct servicing equipment also ensures proper pressure and flow during the compressor wash.”

Performing proper compressor washes can result in many benefits. Removing the contaminants restores engine efficiency, resulting in better fuel economy (Tassone says a 1 to 4 percent fuel savings can be realized). It also results in lower EGT, lower corrosion, and restored performance.

It’s more than just a mundane task after all.