Pioneers: MTU and German Armed Forces Conclude Maintenance Framework Agreement to Support the TP400-D6 Engine for the A400M Fleet

Munich, October 10, 2017 – Over the next five years, MTU Aero Engines, Germany’s leading engine manufacturer, will maintain TP400-D6 engines from the Airbus A400M military transport aircraft for the German Armed Forces. The framework agreement is between the Federal Office of Bundeswehr Equipment, Information Technology and In-Service Support (BAAINBw) and MTU.

“Germany now has an all-encompassing maintenance concept in place for the TP400-D6,” said Michael Schreyögg, MTU’s Chief Program Officer. “We are delighted to be pioneering with the German Armed Forces once again. In 2002, MTU and the German Air Force were the first in the market to establish a cooperation for the maintenance of weapon systems. Now, we are the first certified company to maintain the TP-400-D6 based on civil MRO procedures. Demonstrating, once more, that we embody our role as the leading industrial company for engines operated by the German Armed Forces.”

Colonel Ingo Feierabend of the BAAINBw is also thrilled with the result of the contract negoti-ations: “This agreement ensures the operational readiness of the TP400-D6 engine, and in turn the German Air Force’s A400M fleet, for the next five years. At the same time, the first facility that is DEMAR 145-approved to carry out maintenance of military aeronautical equip-ment is up and running. This marks a milestone that will set the stage for more projects in the future.”

Multi-level maintenance concept

Maintenance of the German A400M engines takes place on several maintenance levels: the German Air Force carries out maintenance and repair work on wing (maintenance levels 1 and 2), whereas more extensive repairs at maintenance levels 2-OFF and 3 are performed by the aviation industry. The aim of the maintenance concept is to guarantee the German Armed Forces receives efficient maintenance services tailored to their operational requirements.

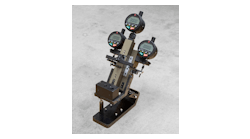

MTU is responsible for the teardown of the engines into their individual modules and accesso-ries. These are then sent to their respective manufacturer for repair and overhaul. The TP400-D6 is a joint project between the major engine manufacturers in Europe: MTU in Germany, Industria de Turbo Propulsores in Spain, Safran Aircraft Engines in France and Rolls-Royce in the United Kingdom cooperate as part of the Europrop International (EPI) engine consortium. Each of the partners carries out module repair respective to its work share. MTU’s stake comprises the intermediate-pressure section – intermediate-pressure compressor, intermedi-ate-pressure turbine and intermediate-pressure shaft – plus the final assembly of all produc-tion engines. Following the return of the repaired modules, the engines are re-assembled at MTU and then sent to MTU Maintenance Berlin-Brandenburg, where the acceptance tests take place. The Ludwigsfelde-based facility boasts the only production test cell for the TP400-D6 engine – one of the most advanced worldwide.

The TP400-D6 is the Western world's most powerful turboprop engine; an A400M military transport aircraft is powered by four of the propulsion systems. The three-shaft engine fea-tures a propeller with a diameter of 5.3 meters and delivers a maximum output of 11,000 shaft horsepower. The German Air Force put its first Airbus military transport aircraft into ser-vice three years ago. In total, the German Armed Forces will receive 53 of the transporters.

New ground was broken with the TP400-D6 maintenance concept for many reasons. While the TP400-D6 is used on a military aircraft, it has been certified to civil aviation standards. Therefore, the maintenance work must be coordinated accordingly. The rules and guidelines developed were integrated in the new European Military Airworthiness Requirements (EMAR); implementation is governed by DEMAR145, which specifies the requirements for mainte-nance organizations in Germany.

About MTU Aero Engines

MTU Aero Engines AG is Germany's leading engine manufacturer. The company is a technological leader in low-pressure turbines, high-pressure compressors, turbine center frames as well as manufacturing processes and repair techniques. In the commercial OEM business, the company plays a key role in the development, manufac-turing and marketing of high-tech components together with international partners. Some 30 percent of today’s active aircraft in service worldwide have MTU components on board. In the commercial maintenance sector the company ranks among the top 5 service providers for commercial aircraft engines and industrial gas turbines. The activities are combined under the roof of MTU Maintenance. In the military arena, MTU Aero Engines is Germany's industrial lead company for practically all engines operated by the country's military. MTU operates a network of locations around the globe; Munich is home to its corporate headquarters. In fiscal 2016, the company had a workforce of some 9,000 employees and posted consolidated sales of approximately 4.7 billion euros.